In part two of our Love Your Linens Care Series, we’re look at common problems in linen care, how to avoid them and the importance of sourcing quality linens from trusted suppliers.

We approached LTC Worldwide to get advice from the experts, here’s what they had to say:

Linen manufacture is an art, which involves both science and skill. With experience, a fabric can be produce which delights the user with its visual and tangible quality, even after 200 washes.

Common Problems

Pilling or bobbling of the fabric is avoided by selection of fibre quality and yarn twist, to produce a soft fabric handle and drape, so that negligible fibres are released during use and laundering.

Sharp creases that cannot be ironed out are avoided by correct de-sizing and a final textile finish, so the fabric looks superb and feels soft to the touch after just a single wash.

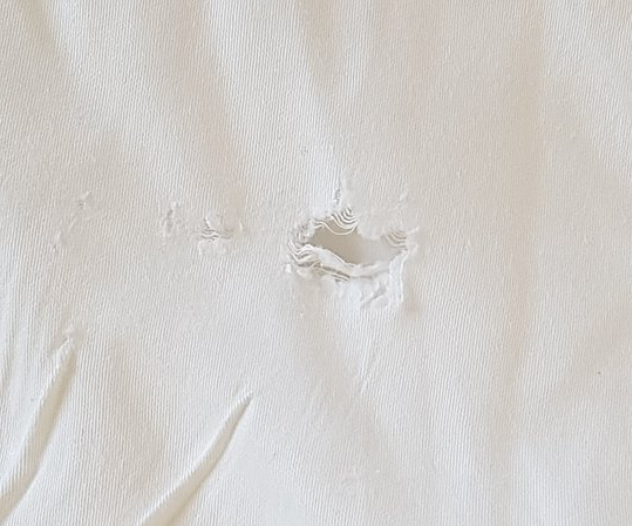

Poor quality linens tear prematurely. Stubborn creasing can result if fabric has not been correctly de-sized or finished.

Premature tears and holes are prevented by uniformity in manufacture and by blending fibres correctly and accurately during yarn spinning.

Greying and yellowing are minimised by correct final treatment to achieve bright, fluorescent whites to dazzle the user. This minimises the risk of greying or yellowing, with correct laundering.

Avoiding disappointment

Don’t be tempted to buy on price alone. Cheap fabrics simply won’t last and may not be produced ethically. Check how the product looks and feels, test the tear strength after one wash. Compare the whiteness with that of your existing stock, both indoors and in bright daylight. Then buy with confidence!

> Discover how One washTM technology can save you time and money when it comes to new linen stock.